Your Cart is Empty

Add your favorite items to your cart.

Shop Now

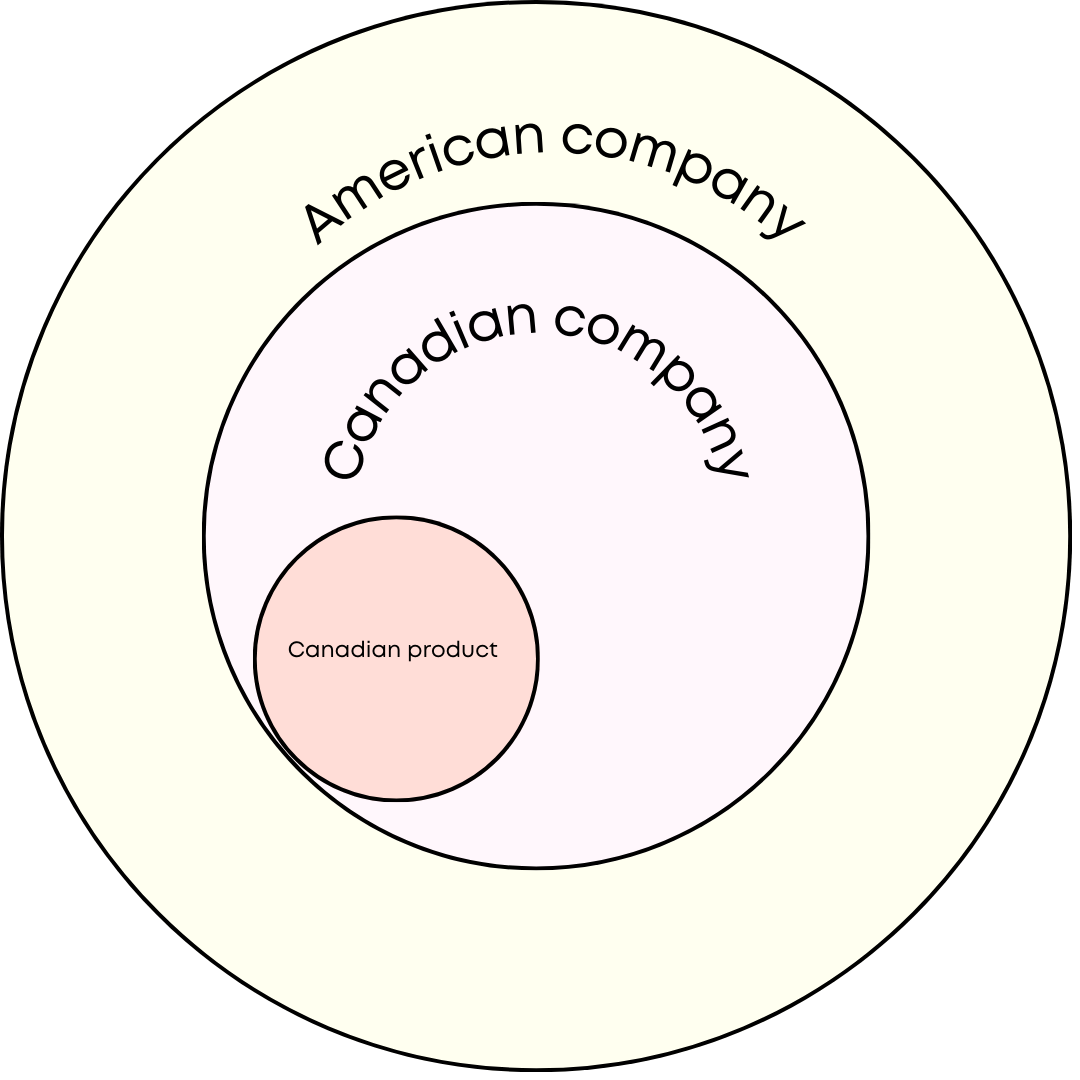

The Government of Canada regulates what counts as a Canadian product. There are two levels to this: a product of Canada, which is food that was virtually entirely produced in Canada (including almost all ingredients, processing, and labour), and food that can say it was "Made in Canada", which means that it may contain ingredients from outside of Canada but the last step, the "substantial transformation" of the ingredients into the finished food, happens in Canada.

There are levels to things that are made in Canada - how many ingredients are from Canada? Where is it processed? Where is it prepared? What if the corporation that owns the Canada-based company is international? These are all factors that may influence your decision to buy the product, and requires research and how many of these levels you are comfortable with to purchase a product.

The backbone of our gummies are made from pea fibre, which is grown from pea crops around Alberta and processed into syrup in Edmonton.

We use sugar derived from beets that are grown in Taber in southern Alberta.

A natural sweetener in our gummies is from honey, which is from hives that are from Spruce Grove, just outside of Edmonton.

Gummy Nutrition Lab is located in Edmonton, Alberta. Here, we have a small factory and laboratory (in the same building!) where food scientists create and produce our gummies- no part of the process is outsourced.

Step 1:

From the conception, mixing ingredients, trouble shooting early batches, and taste testing, our food scientists work in our lab to mix and cook the perfect gummy recipes. It's harder than you might think - once an idea for a nutraceutical gummy begins testing, they go through countless iterations to get the ultimate taste, texture, and formula.

Step 2:

Once a gummy recipe is complete, we measure our ingredients and cook up the gummies in the factory in small batches - averaging about 25, 000 gummies! (Yes, this is small compared to a huge international factory.)

Step 3:

Once the gummies have cooked, they're pumped into the gummy depositing machine, which measures and deposits the gummy liquid into moulds on a conveyor belt. The gummies are cooled in the fridge to help them set, then popped out of the moulds and dried to the perfect texture.

Step 4:

After drying, our production staff hand-pack all of our gummies into our custom packaging, which is then shipped right from our factory to stores - and to you when you order from the website!